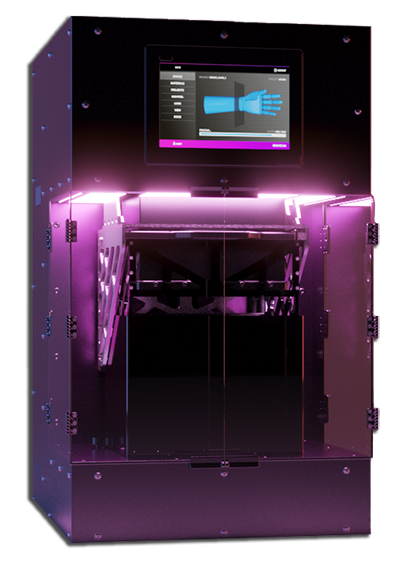

Resin 3D printing redefined

With Multidimensional Additive Production, it has become a reality to grow your resin parts at unprecedented speeds simultaneously, while reducing it's support structure need

DUPLEX S2 is developed based on the patented MAP™ technology, enabling the printing of an object from two different directions at the same time in excellent detail.

It is an SLA based process designed to leverage the benefits of multiple directional printing.

What makes DUPLEX S2 unique?

Less or no support material needed for most geometries

Double printing speed

without decrease in resolution and regardless of geometry

Fully

automated system

Real Science

Complex algorithm to support 2-way part growing

Project Management

Organized handling of your printing projects

Clean UI

Intuitive and informative status screens for easy monitoring of your print processes.

Patent exploitation for the SLA MAP™ technology is for sale.

DUPLEX S2

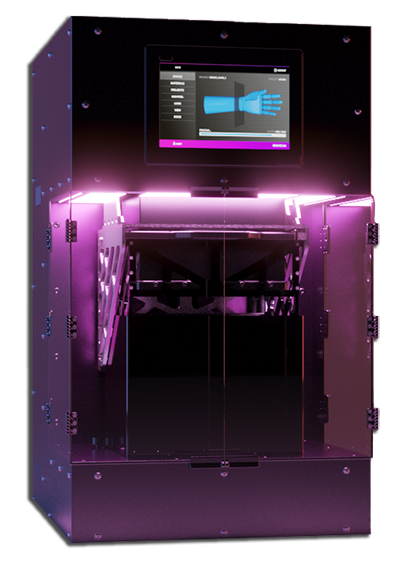

Technical Parameters

Built Volume

Built Volume: 200 x 120 x 300mm

Machine Dimensions: 550 x 600 x 900mm

Weight – 85kg

Z layer resolution 25 – 100 micron

Cloud based software control

Fully automated system

Features

Interchangeable mid-plate

Resin tank for 7kgs of printing resin

XY resolution of 77 microns

Z layer resolution 50 microns

Cloud based software control

Fully automated system