The new generation of FDM printers!

DUPLEX F2 is developed based on the patented MAP™ technology, enabling the printing of an object from two different directions at the same time.

The new DUPLEX F2 printer is designed for heavy, industrial application, built from quality parts and assembled with precision to assure the long lasting quality and reliability this new technology truly deserves. Thanks to the multi-directional part growing, the DUPLEX F2 gives up to 15-times faster total production process than other FDM printers due to the combination of its unique features

Benefits

Less to no supports

Support structures are unnecessary for most of shapes

Fully automated

Autonomous operation of multiple print directions

Wide range of thermoplastics

Applicable for PLA, PET, ABS, ASA, PP, PA & CF/GF reinforced PA

Designed for elongated, complex shapes

Build chamber designed to fit most parts in our target industries

Smart processing

Proprietary slicing software to handle two-way printing

High speed printing

Optimized for BASF filaments including PLA PRO1

Key Innovations

- MAP™ technology: parallel, simultaneous printing from multiple directions of the same object

- AutoPlane System (APS): APS automatically removes the base plate, allowing the bottom extruder to access the object for parallel printing from top and bottom at the same time

- Proprietary DUPLEX software to handle unique MAP™ slicing needs: the DUPLEX processing software is a powerful tool for 2-way part slicing

- Auto check system: advanced part error recognition algorithm

- Mesh auto calibration: mesh plate calibration for perfect part orientation

- Remote support: diagnostics and printing tech support carried out remotely by our DUPLEX specialists

Printed without any support

Technical Specs

Built Volume

∅ 400 mm x 1000 mm

Machine Dimensions

912 mm x 1176 mm x 2654 mm

Custom build plate

up to 180 C

Heated Chamber

up to 80 C

Z layer resolution

50 – 600 micron

Web-based remote software control

Fully automated thermal control system

Automated mid-section operation for high quality two-way printing

Technical Specs

Built Volume

Diameter – 400mm

Height – 1000mm

Machine Dimensions

Width – 880mm

Debth – 106mm

Height – 2400mm

Features

PEI covered print plate up to 130 C

Heated Chamber up to 80 C

Z layer resolution 50 – 600 micron

Remote software control

Fully automated system

Fully automated sytem

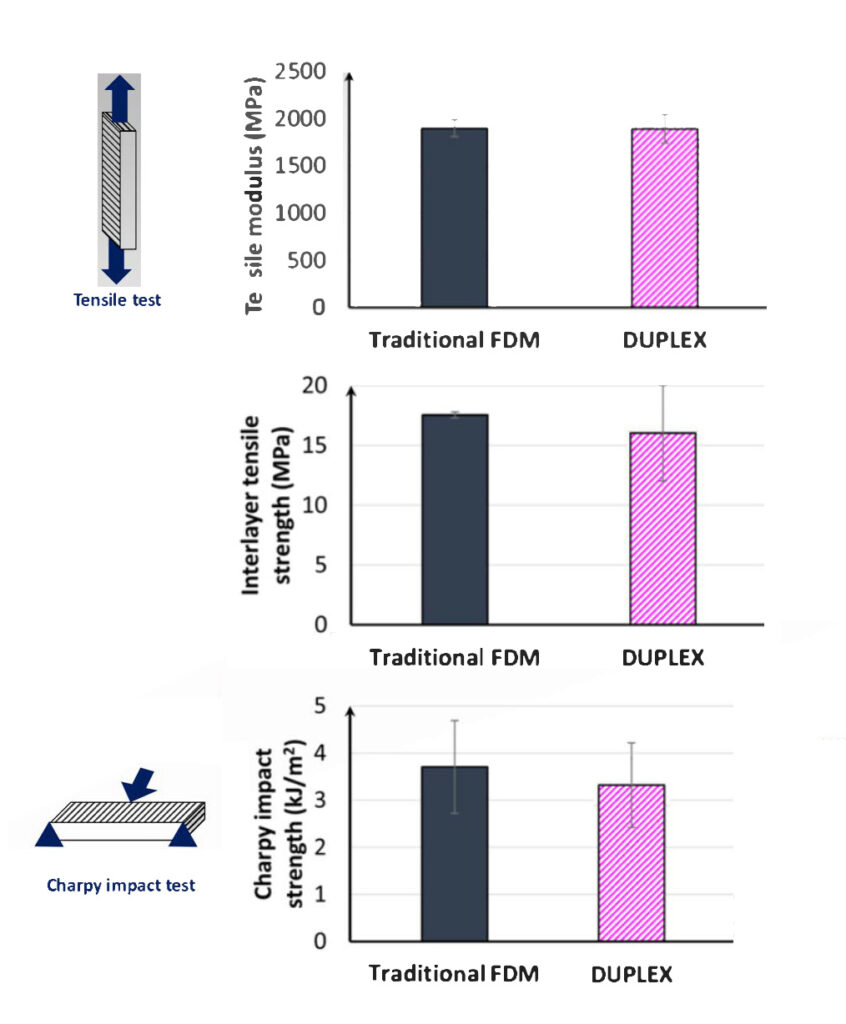

Same mechanical properties as one-directional printing

Independent testing carried out by the Polymer Department of the Budapest University of Technology

For independent mesurements of the F2’s printered parts, the company has contacted the Faculty of Polymer Technology at the Budapest University os Technology and Economics. Their measurements on a kayak paddle part are published on this page.

Test Results

Tensile test results showed that there is no significant difference between conventional FDM 3D printing and two-way building of parts, with the latter causing only a slight reduction in the interlayer strength and the modulus remains unchanged.

Charpy impact tests also showed a slight reduction in average impact strength, although the difference is not considered significant due to overlapping scatter fields.