Complex

Pipeline

Pipeline

System

in hours

in hours

Problem

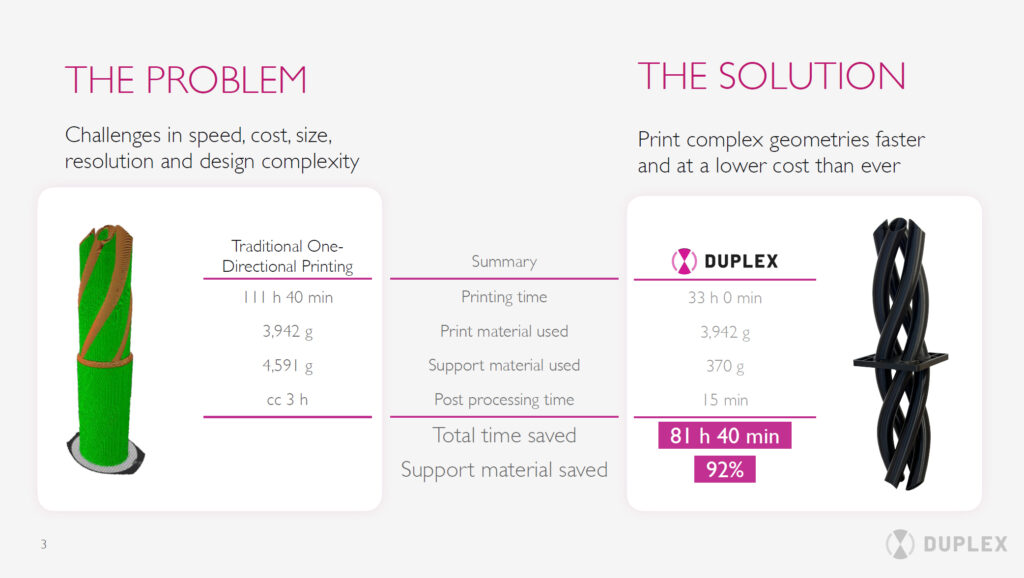

The conventional 3D printing process presents limitations when it comes to printing complex and elongated shapes, as it requires extensive supporting. This not only increases the printing time significantly, but also makes it challenging to post-process the final print.

Due to these underlying challenges and resulting inefficiencies, sectors such as Machine Manufacturing, Pharmaceuticals or Water Treatment Industries often look for alternative prototyping methods, that can be more time-consuming and expensive than 3D printing.

Solution

The DUPLEX F2 printer with its patented MAP technology eliminates the need for extensive supporting and reduces printing time significantly, making the post-processing of prints easier and more efficient.

This innovative two-directional printing technology makes it possible to 3D print complex shapes, like a Pipeline System or Junction, and thus is an ideal solution for industries looking to streamline their innovation lead-time.